Within the flow of a company's supply chain planning process, the breakdown of functional silos and the integration of the various business areas involved, have long been endorsed. However, even with the adoption of integrated management systems, achieving tangible and quantifiable results remains a challenge for most companies. Within this scenario, companies are increasingly implementing the Sales and Operations Planning (S&OP) process, using straightforward practices that aim to simultaneously achieve improvements in terms of cost (inventory levels and cost of production) and service (product availability).

These overall results are achieved by improving the sales and production planning process, based on a balance not only between demand and product availability (encompassing production and supplies) , but also between volume and product mix.

Critical Success Factors

S&OP is basically a fairly simple process, that encompasses two activities - demand forecasting methods and inventory planning - already discussed at meetings and carried out by a company. However, to be successful, the S&OP process requires a combination of factors to be implemented, as follows:

Commitment of the company

The first aspect to be considered concerns the degree of effective involvement of the company's management body in the S&OP process. How often are managers present at meetings and what is their level of interaction when it comes to decision-makings?

The second aspect concerns the involvement of all areas directly or indirectly affected by the material inventory planning process. As an example of an indirectly related area, we can cite maintenance or engineering. In some cases, changes from scheduled downtime to maintenance may be necessary to free up production capacity in order to meet the demand planning. Based on this example, it is possible to identify the importance of not only the presence of all areas with some relation to material requirements planning, but also that managers in these areas have the authority to make decisions.

Meeting Planning

Due to the many unfolding events that can impact sales and production planning, S&OP meetings are very often subject to lack of focus and to discussions about specific and less relevant points. Thus, meetings should be planned in such a way as to follow a set agenda for the main points to be discussed in order to prevent minor issues gaining undue importance.

Try our fast & simple demand forecasting solution

Sign up for free to SKU Science today!

Pre-loaded sample data - No credit card required

Definition of responsibilities

In addition to clarifying the responsibilities of the managers of each area within the process, it is advisable to designate a sponsor and a person responsible for the S&OP process as a whole. It is the sponsor’s responsibility to keep the entire company’s attention on the process; to remove possible impediments to incorporate necessary additional resources (participation of new people, or acquisition of supporting tools), and finally, to provide general support to the process. With respect to the person in charge of the process, their main responsibility is to manage the execution of each stages of the process, including the fulfillment of the defined deadlines, and to conduct planning meetings.

Planning horizon

This relates not only to the total planning period, but also to the point at which planning becomes more detailed (for example, planning for five months, but detailing the production mix for the next month only), and the presence or absence of a frozen planning period. The importance of these definitions is based on the specific need for planning by each area involved. For example, the supply area may require demand planning for three months due to purchase constraints, while production may be indifferent to the long-term, but requires a plan for the next month due to its production scheduling.

Supporting tools

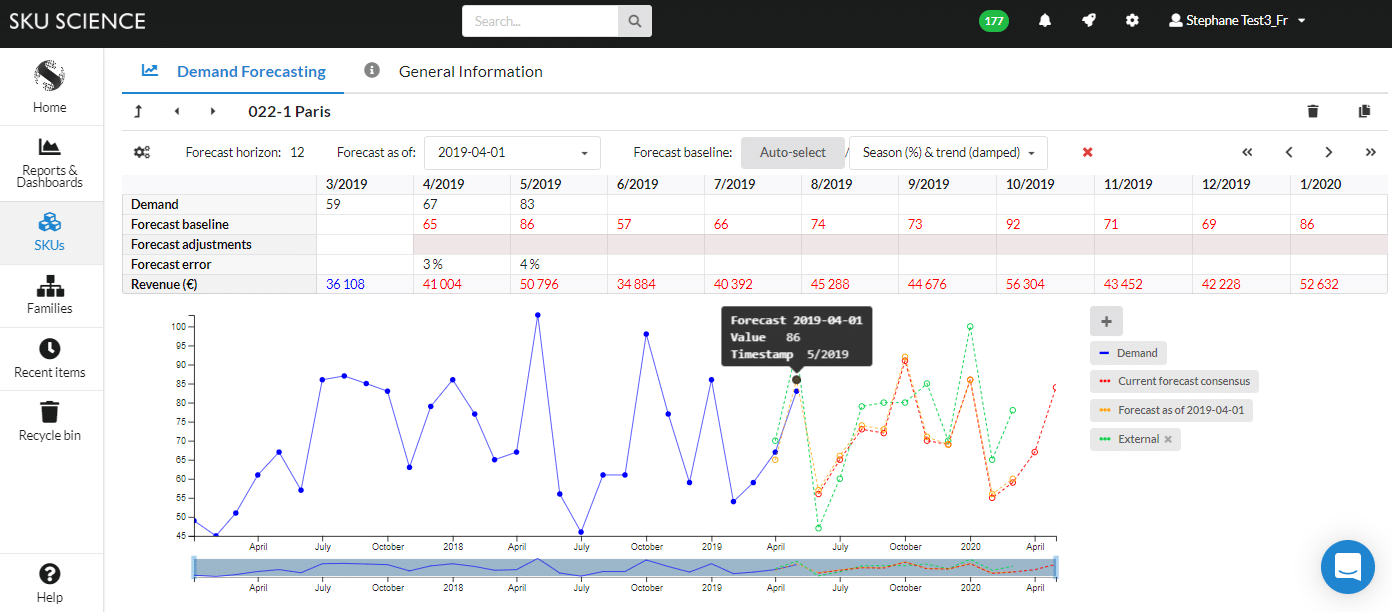

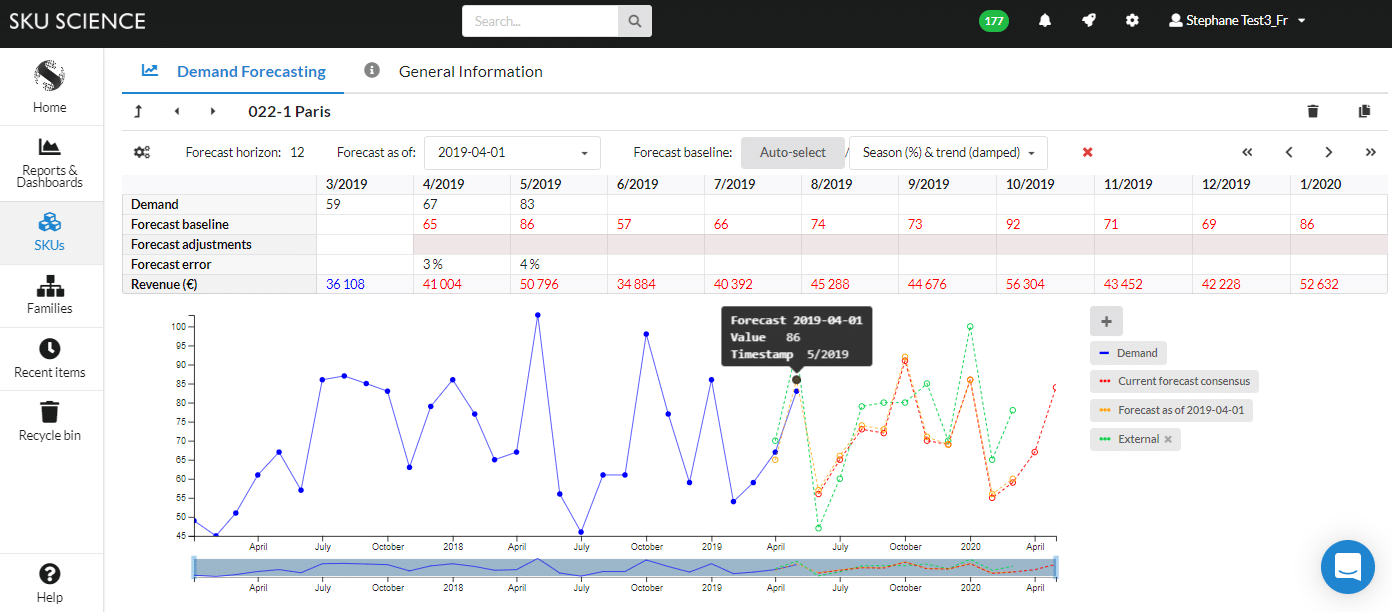

In any planning process that requires some demand forecasting techniques, the use of digital resources and data models is a strong indication that the decisions made adequately take into consideration all trade-offs involved in the problem. For example, there is room to optimize some forecast models by applying several demand planning tools, and using software that enables more accuracy, transparency and agility during the process.

It is worth noting that the use of support tools for each of the planning activities does not depend on the existence of an S&OP process, which may occur before or after the implementation of the S&OP process. The use of these tools, together with the S&OP process, has the effect of amplifying their potentialities; migrating from obtaining local gains to an integrated gain in planning efficiency.

Financial follow-up

S&OP meetings can be used to monitor and review the company's overall budget, not only from a volume standpoint but also from revenue and profitability. This influence on the financial aspect occurs through possible changes in the planning of the sales mix. In this way, it is advisable to evaluate the impact of all planning alternatives discussed throughout the meetings. This evaluation can be carried out before the actual meeting, or even during the meeting, which gives greater flexibility and dynamics to the process. However, it does require a higher level of efficiency from decision support tools.

Documentation of the process

The degree of formalization of an S&OP process usually has a strong relationship with the documentation level of the process. Thus successful processes are expected to have a documented detailed planning policy that includes the participants, the responsibilities, the deadlines, and the objectives for each step of the process.

Performance Monitoring

In line with the financial monitoring aspect, monitoring the S&OP process should address both the performance as a whole, as well as the activities of each area involved in the process that may have an impact on its final performance.

From the point of view of the final outcome of the process, it is important to monitor the availability of products for sales and inventory levels, in addition, of course, to the financial results of the company as a whole discussed above. In this respect, it is advisable to use a proper supply chain dashboard. With regard to the specific activities of each participating area of the planning process, we can cite the accuracy of the sales forecast, the fulfillment of the production plan and the final productivity of the period.

Conclusion

Based on this list of critical success factors, one can conclude that, while seemingly simple, implementing the S&OP process can be complicated. However, the most important conclusion is that, in considering the deployment of S&OP as an evolutionary process, the actions required to reach a satisfactory stage from the results standpoint are not complex. Therefore, there is no reason to fear the implementation of such a practice. It can be initiated in a very simple way and evolve in terms of complexity and investments.The positive results achieved by S&OP are proof that companies can place increasing confidence in the process, and they are encouraging for those businesses that have yet to take the first step.